Success Story from Particle Foam

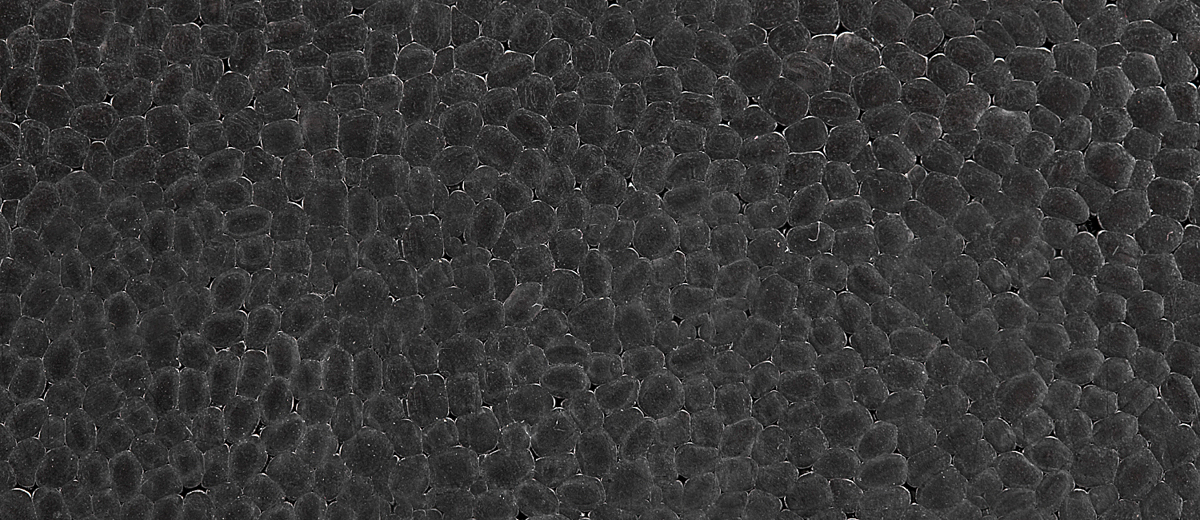

Styropor®, also known as EPS (expandable polystyrene), is a thermoplastic particle foam based on polystyrene. Styropor® offers so many advantages due to its excellent material properties that it is difficult to list them in a factually correct order. Different objectives usually result in different priorities – but whatever they are: Styropor® serves almost all preferences in an optimal way.

Styropor® consists of 98% air and only 2% structural substance, and it is precisely this fact that gives this material its excellent property profile. This also results in extraordinary cost-effectiveness, which is characterized by a very favorable price-performance ratio.

EPS-Re, also known as Styrofoam with recycled content, represents an innovative solution in the field of sustainable packaging. The material combines the proven properties of conventional Styrofoam with the environmental friendliness of recycled raw materials. By using recycled EPS with up to 30% recycled content, the demand for new raw materials is reduced, which contributes to reducing the ecological footprint (CO₂ footprint).

The production of EPS-Re is achieved through the reprocessing of used Styrofoam products. These are collected, processed, and recycled before being reintroduced into the production process. This results in a high-quality material that exhibits the same insulating and protective properties as conventional EPS. The use of recycled Styrofoam not only promotes the circular economy but also makes an important contribution towards a more sustainable value chain.

airpop® is a harmonized brand name across Europe for the widely known Styropor® (EPS) in Germany. This new terminology is an attempt to internationally align the existing variety of names for this material.