Packaging and Logistics for the Automotive Industry

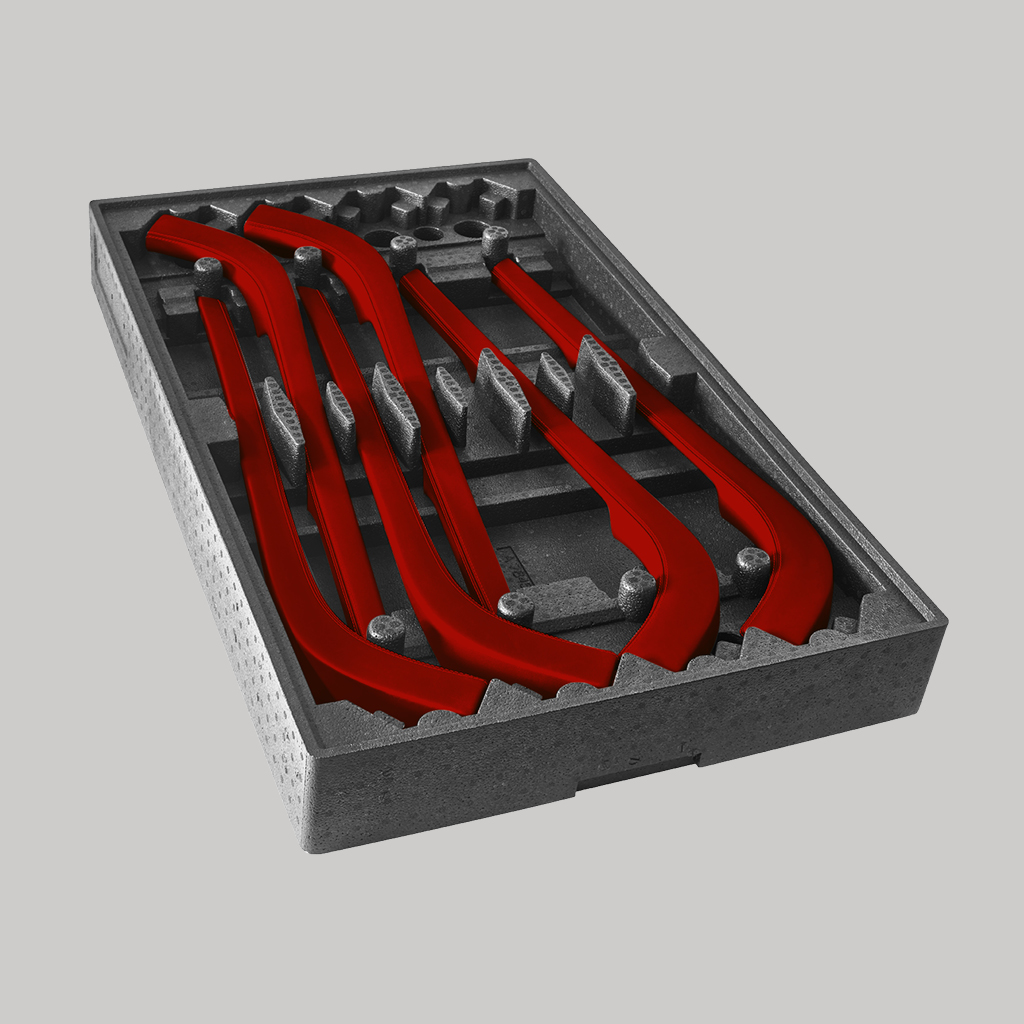

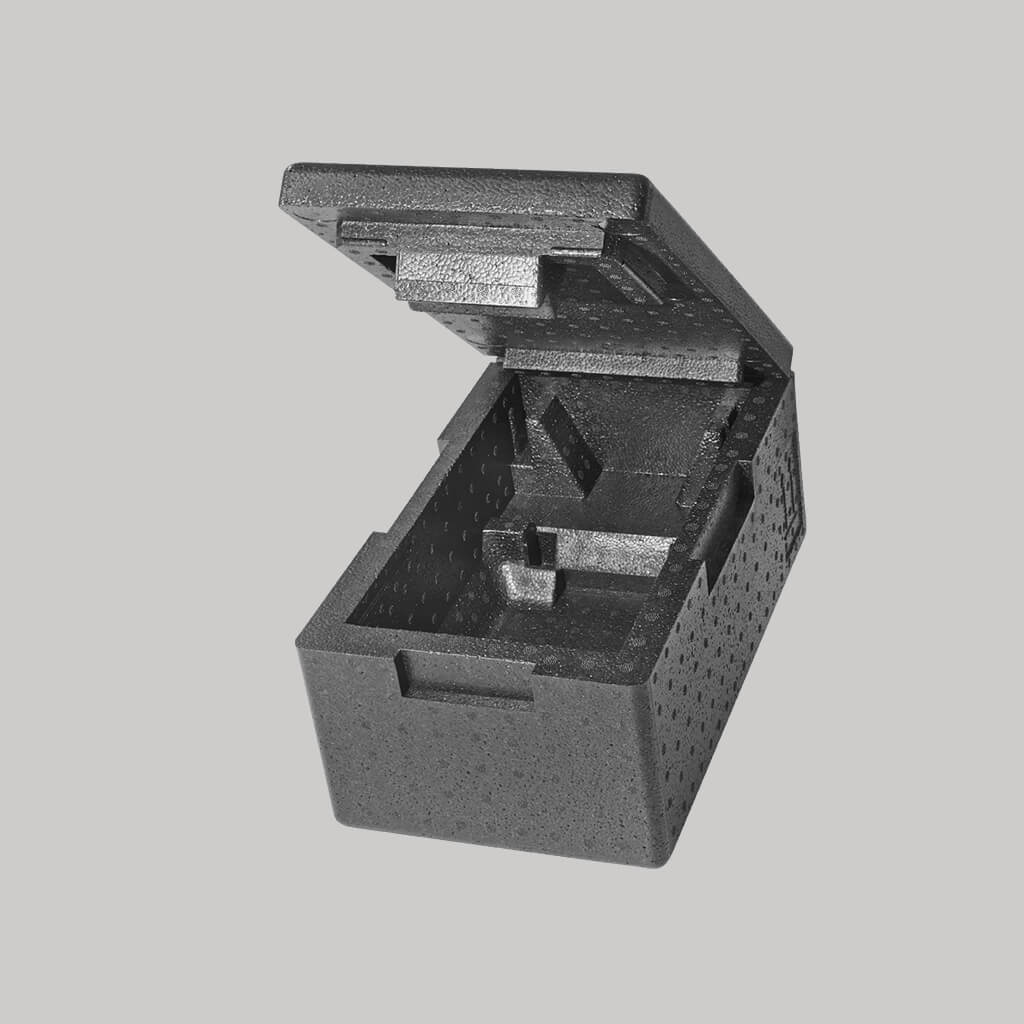

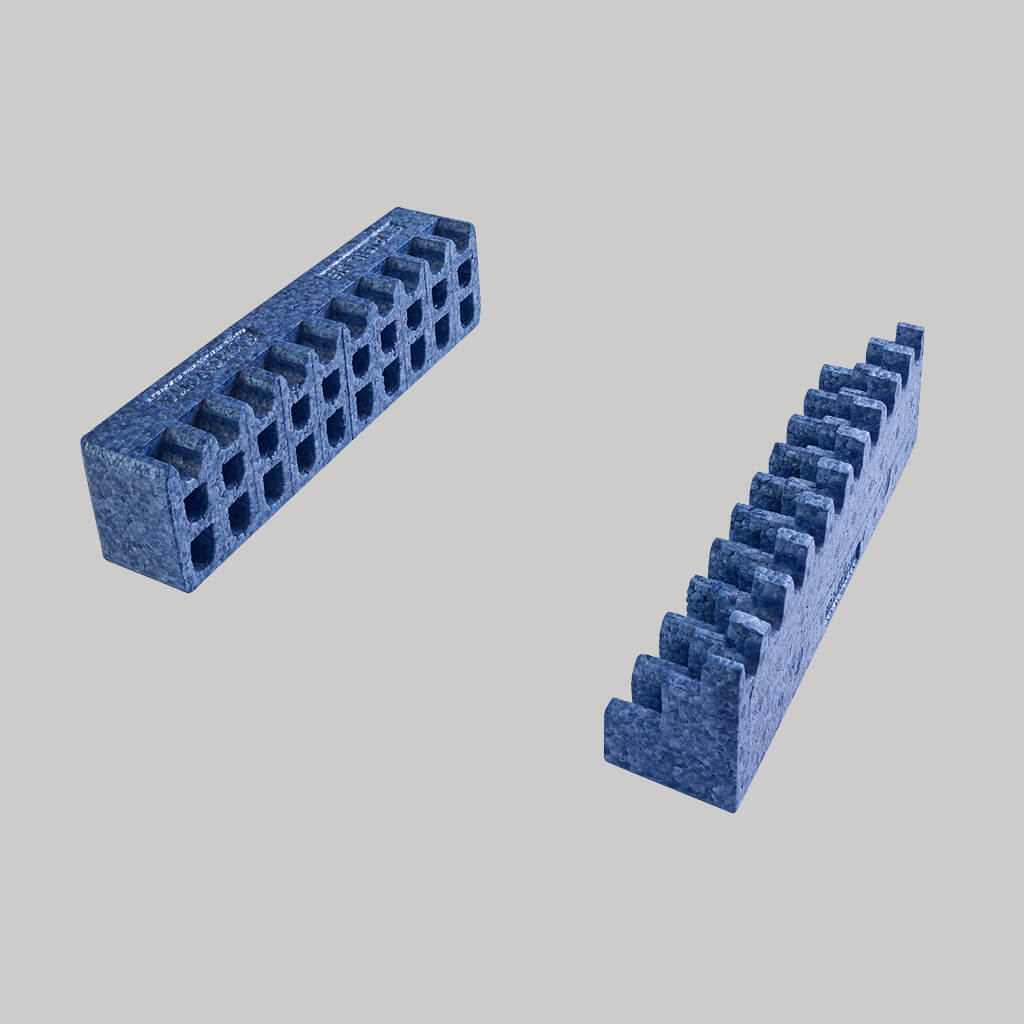

With our EPP load carriers, important vehicle parts arrive safely at the customer. EPP molded parts are excellently suited for the most demanding packaging and transport tasks in the automotive industry due to their special energy absorption capacity and resilience properties. It’s no coincidence that air suspension has become established in commercial vehicle construction. The shock-absorbing effect of our particle foams (EPP, EPE, copolymers) is based on a similar principle. Countless EPP stacking containers developed by us and in use are the best proof of the robustness of these reusable shuttle packaging. The smooth, elastic surface feels waxy: It provides reliable protection for sensitive paint finishes, plastic surfaces, or polished glasses.

- Car Lights

- Windows

- Exterior and Interior Mirrors

- Pillar Trims

- Locking Systems

- Airbag Systems

- Interior Components

Our EPP molded parts are also excellently suited for transporting heavy loads. They withstand shocks and pressure loads permanently, are stackable and palletizable, and usually last for the life of a car. This way, you keep your logistics costs under control.

For export, you can of course also get our load carriers in a cost-effective disposable solution made of Styropor® or copolymers.

+49 6726 – 803 – 136

- Robust shuttle packaging

- Multi-shock capable

- Electrostatically conductive

- Non-detachable lid due to hinge solution

- EPP load carriers are the ideal packaging materials for sensitive goods with delicate surfaces

- Their application extends across various industries and functions

- Due to their robustness, EPP trays and inserts are reusable (shuttle packaging) and therefore predestined for cost-effective logistics

- Trays and inlays are also available in speckled or colored versions for differentiation

- Schlaadt has a variety of standard covers. This helps minimize tool costs